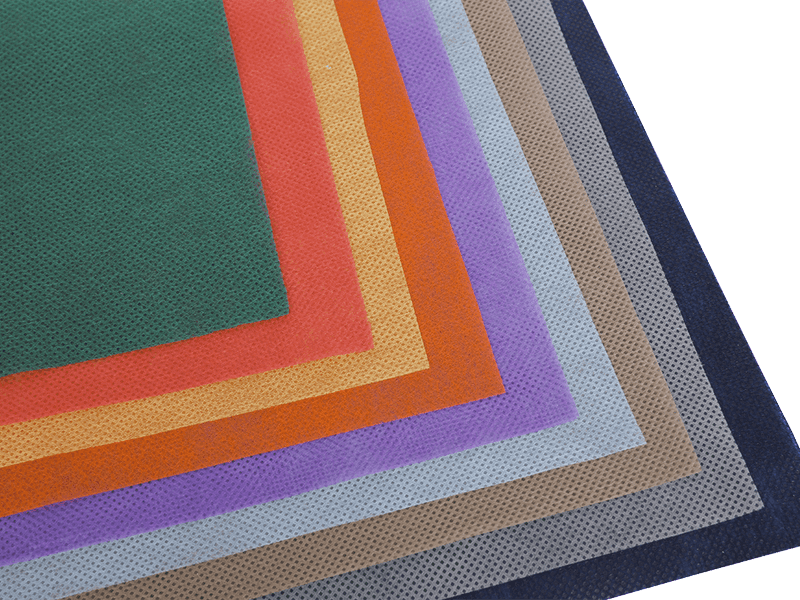

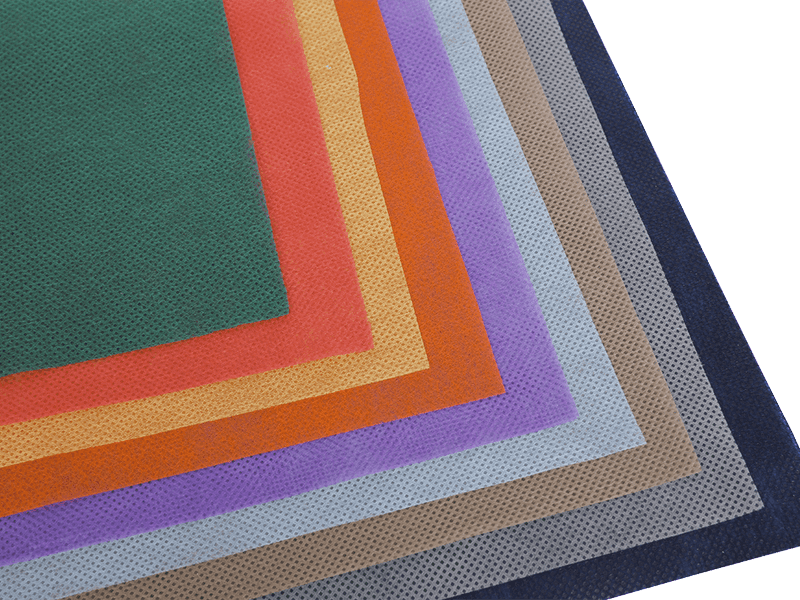

SMS nonwoven fabric is a three-layer structure composite material commonly used to manufacture medical masks, surgical gowns, sanitary napkins, toilet paper and other products. The properties of this nonwoven may vary under different environmental conditions. The following are some environmental factors that may affect the performance of SMS nonwovens:

Humidity: High humidity may affect the breathability of sms nonwoven fabric. The breathability of nonwovens may decrease under high humidity conditions, which may affect wearer comfort, especially in medical applications that require prolonged wear.

Temperature: High-temperature environments may cause changes in the meltblown layer (Meltblown layer) of SMS nonwoven fabric, thereby affecting its filtration performance. In high-temperature environments, the molten layer may become softer, affecting the structure and performance of the non-woven fabric.

Chemical Substances: SMS nonwovens exposed to chemicals may be corroded or altered. Certain chemicals may affect the physical properties and chemical stability of SMS nonwoven fabrics.

Ultraviolet radiation: Prolonged exposure to ultraviolet light may cause the SMS non-woven fabric to age, causing it to lose some of its original properties.

Mechanical stress: SMS nonwovens may change under tensile or other mechanical stress. This is important for applications that require tear-resistant properties, such as in some medical uses.

Overall, SMS nonwoven is a material designed to provide specific performance in a variety of environmental conditions. Its performance characteristics may vary under different environmental conditions, so these factors need to be considered in specific applications to ensure that its performance meets expected requirements.